- Home

- L'azienda

-

Catalogo Prodotti

- AREA INCHIOSTRI

- AREA ATTREZZATURE

- AREA PRESTAMPA

-

Servizi

- IN HOUSE

- ON SITE

- ON LINE

- Contatti

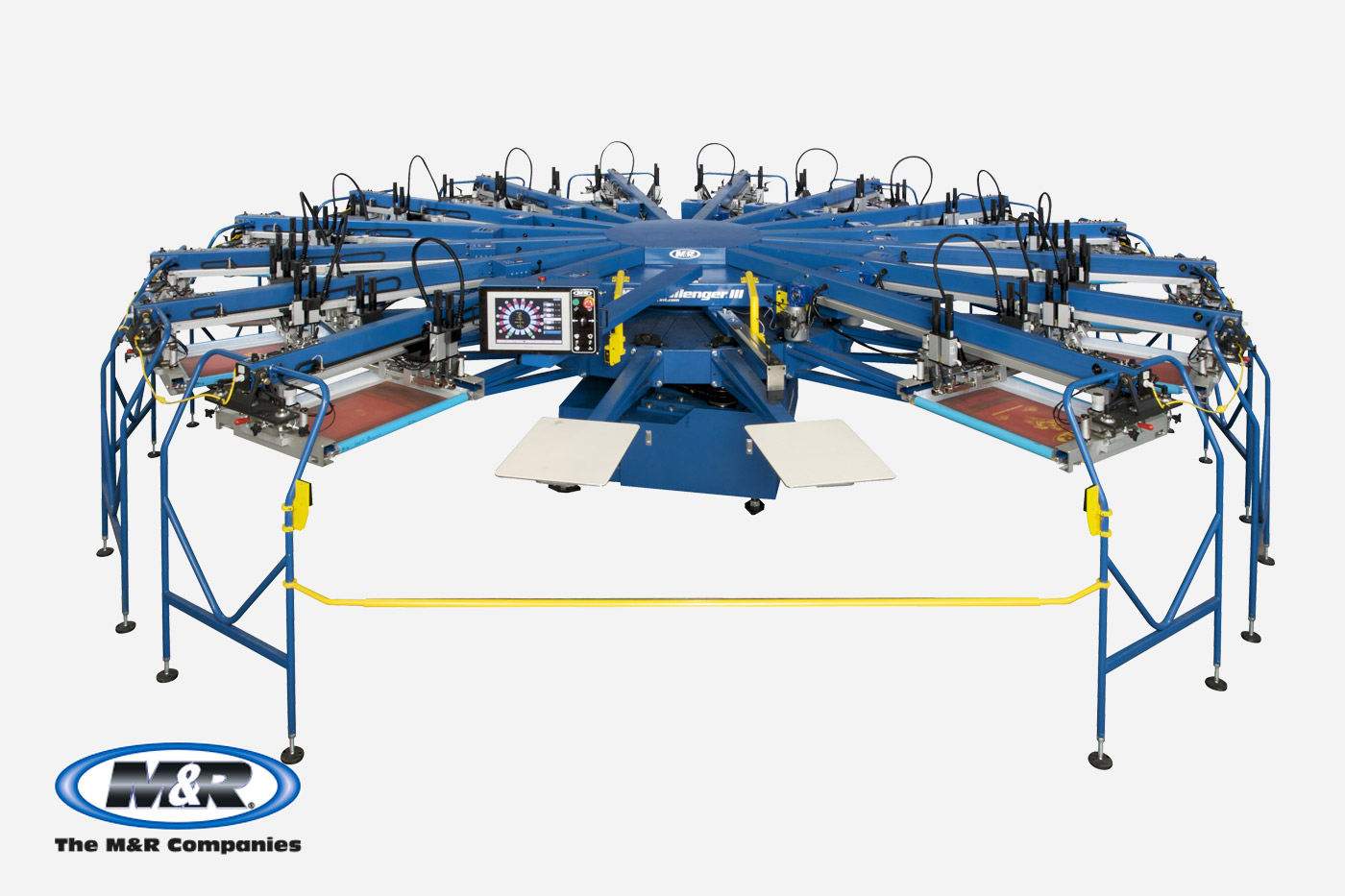

Challenger revolutionized screen printing in the 1980s, and Challengers have dominated the industry ever since. M&R’s Challenger III automatic screen printing press expands on that tradition by combining innovative features—like M&R’s electronically adjustable Ink Dip™ ink retrieval system—with exceptional speed and the best ideas from over 25 years of M&R automatics. Challenger III’s indexer enables double indexing in one uninterrupted motion, increasing production speed for oversize work by eliminating the pause between indexes. Challenger III automatic screen printing machines feature printheads driven by fast, reliable electric-drive motors. The printheads include calibrated tool-free click-stop four-corner off-contact settings for fast and accurate screen leveling.

All Challenger III automatic screen printing presses include tool-free front and rear print-stroke adjustment for versatility and exceptionally high production rates. Pneumatic screen clamps facilitate rapid screen loading and deliver excellent stability on a wide variety of screens. M&R’s Laser Locator System speeds pallet positioning and changeover, and it assists operators in the precise positioning of garments and cut-piece goods. The squeegee/floodbar park feature facilitates setup and tear-down by simultaneously retracting the squeegee and floodbar and then moving them to the outside edge of the press for easy access. Other standard features include squeegee pressure regulators; independent squeegee & floodbar speed adjustments; independently-set angle and calibrated squeegee and floodbar pressure adjustments; and adjustable rear screen holders. Unlike side screen holders, which severely limit the maximum screen-frame width and maximum image area, front and rear screen holders allow easy placement of extra-wide screens for oversize and all-over screen printing. Print, reset, and print/flood speed controls on each printhead further simplify setup. Each printhead also features a socket that makes it easy to position a flash cure unit in any screen printing station. Challenger III 110 models include a wider print carriage for enhanced print quality. M&R’s Automatic Pallet Preheat Mode™ with built-in pallet temperature sensor allows operators to preheat pallets to the desired temperature with any compatible flash cure unit and track those temperatures throughout the print run.

Challenger III was built from the ground up to optimize speed, performance, flexibility, print quality, and durability. With a large touchscreen control panel featuring icon-based labeling that can display information and commands in multiple languages; an extensive variety of configurations; an unrivaled set of standard features and timesaving, output-enhancing exclusives; efficient design; and high production speed, Challenger III is poised to dominate the next decade of automatic screen printing.